Bias Ply OR Radial

27th Jul 2016

It’s a decision that every collector vehicle enthusiast faces at some point in his or her life. Do you want the period correct look and feel of a cross ply tyre, or do you want the comfort and reliability of a modern radial? Both types of tyre construction have pros and cons in the collector vehicle world, but it’s important to be educated on the matter before spending money on a set of tyres.

Modern blackwall radials to fit 14- and 15-inch wheels are still readily available at most local tyre stores, but they just don’t have the correct look. Although modern radials from your local tyre shop are safe and provide an adequate ride quality, they certainly don’t add to a collector vehicle’s authenticity like a set of specialty tyres. You have the decision of bias ply or radial, and of course the all-important decision of whitewall, redline, white letter or blackwall, so choose carefully and hit the road with confidence.

Bias Ply Tyres

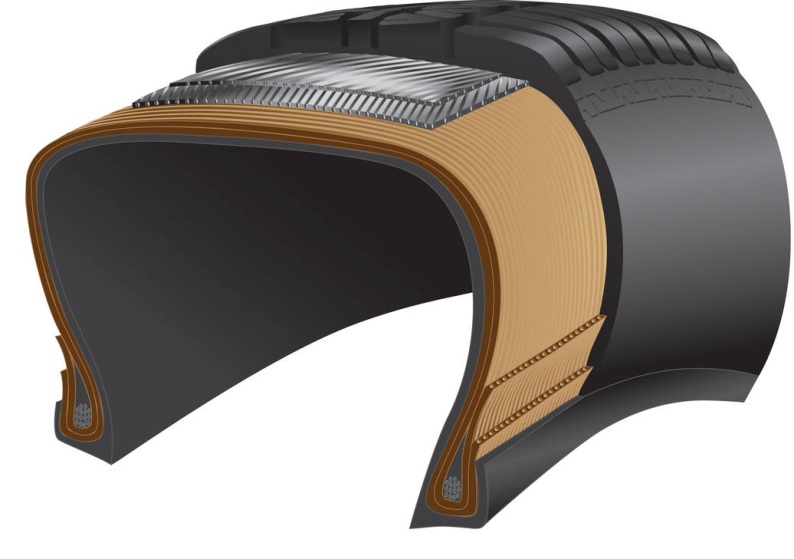

The specialty tyre market has typically been divided into two segments—bias ply and radial. The term “bias ply” refers to the internal construction of the tyre. In a bias ply tyre, the cords (plies) run at a 45-degree angle (cross ply) from bead to bead. This diagonal pattern is criss-crossed with each layer of ply cord, and creates a very rigid structure. In the vintage car market, bias ply tyres feature a narrow tread profile, with a sharp shoulder that usually has a piecrust look. The narrow tread pattern, and the fact that most bias ply tyres mount to narrow wheels makes for a sidewall bulge that is easily identifiable and adds to the look of vintage cars.

Bias ply tyres are strong, but the rigidity offers some interesting handling characteristics if you’re accustomed to driving on radial tyres. The rigid construction means that bias ply tyres do not conform to the road surface as efficiently as a radial tyre. This creates a “wandering” sensation, as the tyres tend to follow the ruts and breaks in the pavement. This wandering is not hazardous, but it definitely requires the driver to pay more attention, especially at highway speeds.

The major advantage to a bias ply tyre that completely overrides the finicky handling is the authenticity. Bias ply tyres were used on American automobiles until the ‘70s, so if you’re building a car from that era, a bias ply tyre is an appropriate choice. Antique Tyre offers bias ply tyres in many authentic brands, such as Firestone & BFGoodrich.

Radial Tyres

Radial tyres are a popular upgrade for collector enthusiasts who plan to get out and drive their old car. The more modern construction offers great improvements, including ride quality, wet weather traction and tread life, so it is a more practical option for most people. The advantages are created by the tyre’s construction, which consists of ply cords that run 90 degrees in relation to the bead. This radial orientation of the cords allow for a more flexible design, which conforms to the road surface, and allows the tyres to skim across the ruts and breaks in the surface. This makes for a pleasant ride quality, even on rough roads, which would cause the wandering sensation with bias ply tyres.

In most cases, a radial tyre will have a wider footprint, even if it is the equivalent size to a bias ply tyre. For instance, a 6.70-15 tyre (common for late ‘40s to mid-50s passenger cars) has the P-metric radial sizing equivalent to a 205/75R15 tyre. However, the radial equivalent features a wider tread surface by more than one inch. This increased contact patch offers more traction and more stability, while the rounded shoulder provides additional traction in hard cornering situations. Radial tyres also feature tread siping, which helps evacuate water from the tread surface, and thus, increase wet weather traction. The drawback to the wider footprint is the modern appearance with the rounded shoulders and wide tread profile, but has recently found a solution for the age-old debate of bias ply versus radial tyres on a collector vehicle.

Bridging the Gap

Until now, car guys have been faced with bias ply versus radial debate and it’s been black-and-white. You were forced to deal with the disadvantages of either tyre style in order to get the advantages that you want. Coker Tyre has successfully blended the qualities of each type of construction into what it considers a “bias look radial” tyre. The American Classic bias look radial is the first of its kind.

The new American Classic radial is immensely popular, thanks to the narrow tread profile, bulged sidewall and aspect ratio of a vintage-style bias ply tyre, with the internal construction of a radial. It's truly the best of both worlds. The American Classic bias look radial is available in several sizes, and fits 13-, 14- and 15-inch wheels, so there are lots of options for O.E. and custom fitments, for cars built in the '40s, '50s and '60s. There are even "big and little" sizes for hot rods. The new tyres are available in wide whitewall and blackwall, providing plenty of options.

The American Classic bias look radials are made in the USA, and they're DOT and ECE (European market) approved. The price is a few bucks more than a comparable whitewall radial out of the Coker catalog, but we'd venture to say that bridging the gap between bias ply and radial is well worth the extra expense.

Tyre Construction

Although tyre construction has changed over the years, the basic principle of a pneumatic tyre has been around for more than 100 years. In the specialty tyre world, many of the tyres are built in low production runs and require special care to ensure a great finished product. For this example, we'll use a whitewall radial, as there are numerous ways to get the whitewall look - some are suggested, while others are not.

So, what's the right way to build a specialty tyre? In terms of build quality, safety and appearance, the correct manufacturing method is to manufacture a tyre that has the sidewall treatment built in from day one. This requires a specific build sheet for the tyre's carcass, and a mold that forms the tyre into its final shape. In the case of a whitewall tyre, the white rubber is added to the tyre carcass, while it is being assembled on the drum, before it is placed in the mold. Then, the mold is built with special reveals that offer a breaking point between the black rubber and white rubber.

If there’s a right way to build a specialty tyre, then you can easily surmise that there is also a wrong way to build a specialty tyre. There are companies that offer port-a-walls, which is a band of white rubber (to simulate a whitewall) that fits between the tyre bead and the wheel. These items are not dangerous or illegal, but they certainly don't qualify as a legitimate specialty tyre. Other companies offer re-capping services that take a modern tyre and vulcanize a vintage style tread cap onto the tyre carcass. Re-caps have been around for many years, but it still isn't a true whitewall tyre.

Another method that could be classified as the "wrong way" to build a specialty tyre is a whitewall that is permanently added to a generic blackwall radial tyre. The whitewall application process involves grinding the sidewalls of an existing tyre (like you'd find at the local tyre store), and vulcanizing white rubber to the sidewall. Not only is the manufacturer taking material off the sidewall, but they are also removing the DOT numbers and other important information that is required by law.